Mastering the Quality Inspection Process for Export

. The Bedrock of QI: The Acceptable Quality Limit (AQL)

The Acceptable Quality Limit (AQL) is the universally accepted standard for defining the maximum number of defects a batch can contain before it is rejected. You must define your AQL criteria before production begins.

A. Setting Your AQL Levels

AQL uses statistical sampling tables to determine how many units from a lot size to inspect, and how many major and minor defects are allowable.

Critical Defects: (Zero allowed) Risks safety, violates mandatory regulations, or renders the product unusable. Example: Electrical short circuit in an appliance.

Major Defects: (Very few allowed) Reduces usability or clearly deviates from specifications. Example: Wrong color coding, a loose component.

Minor Defects: (Low percentage allowed) Slight deviations that do not affect function. Example: Minor scratch in a non-visible area.

Actionable Tip: Always agree on the AQL standard with your manufacturer and your buyer in writing before production begins.

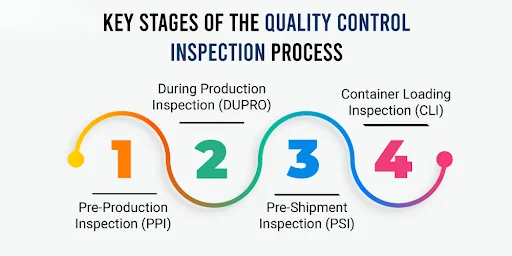

2. The Strategic Timing of Inspection

When you inspect is often as important as what you inspect. Inspections should be phased to catch defects at the most cost-effective moment—before mass production.

| Inspection Type | When It Happens | Primary Goal | Risk Mitigation |

| IPI (Initial Production Inspection) | After 10-20% of the raw materials are checked. | Verify materials, machinery setup, and quality of first run samples. | Prevents mass production of defective goods. |

| DUPRO (During Production Inspection) | When 40-60% of the order is complete. | Checks consistency, monitors production timeline, and addresses mid-cycle issues. | Ensures production flow meets deadlines; addresses recurring minor defects. |

| PSI (Pre-Shipment Inspection) | When 100% of the goods are finished and 80% are packed. | Final check of quality, quantity, packaging, and marking before freight booking. | Essential. Prevents shipping non-compliant or defective goods overseas. |

3. The Export-Specific Inspection Checklist (Beyond the Product)

An export QI goes far beyond the product’s function. It must cover logistical and compliance elements:

A. Product and Functionality Checks

Visual/Aesthetic Checks: Verify color, finish, and dimensions against the approved sample and spec sheet.

Functionality & Safety Tests: Put the product through its paces (e.g., testing electrical components, load-bearing capacity, operational software).

Compliance Markings: Verify mandatory markings (CE, UL, FCC, etc.) are correctly placed, permanent, and legible.

B. Packaging and Logistics Checks

Packaging Integrity: Inspect inner and outer carton strength to ensure they can withstand international shipping conditions (vibration, drops, stacking pressure).

Shipping Marks: Verify the Gross Weight, Net Weight, Dimensions, HS Code, and Port of Destination are accurately and legibly printed on the master carton. Errors here cause customs delays.

Quantity Check: Ensure the physical count matches the invoice and packing list.

4. Documentation and Final Release (The Logistics Hand-off)

The culmination of the QI process is a detailed Inspection Report. This document is vital for internal accountability and external customs audits.

The Report: Must include photographic evidence of the sampling process, detailed defect classifications, and clear pass/fail status.

Final Release: Only upon formal approval (Pass Report) should the factory be given the final payment authorization and the goods be cleared for pickup by your freight forwarder. Do not book freight until the PSI report is approved.

Contact us for more details of & Your registration

Our team will be happy to assist you

Mobile: +91-790-200-2800